根據(jù)焊槍的擺動方式,焊接擺動器可以分為直線擺動方式(俗稱直擺型)和焊槍沿圓弧方向擺動方式(俗稱鐘擺型)。

According to the swing mode of welding gun, welding oscillator can be divided into linear swing mode (commonly known as straight pendulum type) and welding torch swing along the circular direction (commonly known as pendulum type).

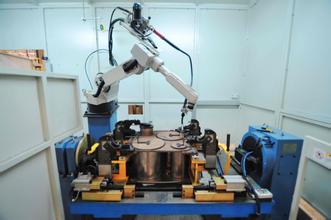

把焊接擺動器固定在小車上,通過擺動小車控制箱的控制電路來控制行走電機,使小車沿焊縫方向前后走動。

The welding swing device is fixed on the trolley, and the control circuit of the control box is controlled by the swing car, so that the car can move forward and backward along the welding direction.

焊接擺動器上裝有限位開關(guān),限位開關(guān)用于當(dāng)焊槍到達極限位置時,產(chǎn)生信號并傳給單片機控制系統(tǒng),使控制系統(tǒng)作出相應(yīng)的控制,來控制焊接擺動器的*大擺幅,保護步進電機。限位開關(guān)另外的作用是使焊槍對中復(fù)位。

The welding oscillator is provided with a limited switch, limit switch is used when the torch reaches the limit position when the signal is generated and passed to the microcomputer control system, the control system to make the corresponding control, to control the welding oscillator swing, stepper motor protection. The limit switch is in effect to make the welding torch in reset.

通過限位開關(guān)的狀態(tài)和面板設(shè)定狀態(tài)來控制步進電機控制器,從而達到控制焊槍擺動的目的。

To control the stepper motor controller through the limit switch state and panel set state, so as to achieve the purpose of controlling the welding torch swing.

通過擺動小車控制箱的控制板和C仇氣體保護焊機之間的RS485通信接口,可以遠程調(diào)節(jié)焊機的焊接參數(shù),方便工人操作。該系統(tǒng)可以實現(xiàn)焊機、行走電機、擺動電機以及送絲電機的同步控制。

The welding parameters of the welding machine can be adjusted remotely through the RS485 communication interface between the control panel and the C gas protection welding machine, which is convenient for workers to operate. The system can realize the synchronous control of welding machine, walking motor, swing motor and wire feeding motor.

泰安揚帆數(shù)控科技有限公司(咨詢電話 0538-5358300)座落在風(fēng)景秀麗的泰山腳下,東平湖畔。東臨泰山 |