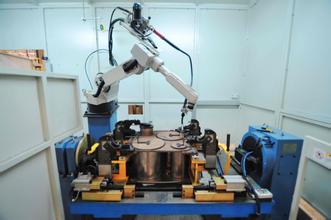

1、焊接過程:參數(shù)能夠分層設(shè)置(包括旋轉(zhuǎn)角度),連續(xù)焊接。焊槍的擺動(dòng)需有自動(dòng)回零功能。焊接圈數(shù)可設(shè)置為1~10圈。

1, welding process: parameters can be set (including rotation angle), continuous welding. The welding torch swing with auto zero function. The number of welding ring can be set to 1 ~ 10.

有高電壓,慢送絲引弧功能,保證引弧可靠;以及低電壓,小電流收弧,填滿弧坑的功能。

With high voltage, slow wire arc function, ensure reliable arc; and low voltage, low current arc crater fill function.

2、焊接電源:采用松下進(jìn)口電源,水冷焊槍,適合長(zhǎng)時(shí)間焊接。帶循環(huán)冷卻水箱不啟動(dòng)時(shí)將發(fā)出報(bào)警并不能啟動(dòng)焊接功能。

2, the welding power supply imported by Matsushita, water-cooled torch, suitable for long time welding. With circulation cooling water tank does not start when the alarm will not start the welding function.

3、采用PLC控制整機(jī)的運(yùn)行和動(dòng)作的協(xié)調(diào),以及在焊接過程中工件的旋轉(zhuǎn)、焊槍的擺動(dòng)頻率、擺動(dòng)幅度、擺動(dòng)時(shí)間,焊槍自動(dòng)提升的時(shí)間、提升距離、提升次數(shù)等。焊槍擺動(dòng)和同步提升采用步進(jìn)電機(jī)控制系統(tǒng),焊接長(zhǎng)度采用閉環(huán)檢測(cè),位置檢測(cè)采用進(jìn)口無觸點(diǎn)開關(guān)檢測(cè)。

3, the coordination of PLC control the operation and action, and in the process of welding workpiece rotation, torch swing frequency, amplitude, oscillation time, torch automatic lifting time, lifting distance, enhance the number of. Torch swing and synchronization to enhance the use of stepper motor control system, welding length using the closed-loop detection, position detection using imported contactless switch detection.

泰安揚(yáng)帆數(shù)控科技有限公司(咨詢電話 0538-5358300)座落在風(fēng)景秀麗的泰山腳下,東平湖畔。東臨泰山,西依黃河,南與孔孟故里相望。京滬高鐵、濟(jì)廣高速公路貫穿而過,交通非常便利。

泰安揚(yáng)帆數(shù)控科技有限公司目前是該地區(qū)一家專業(yè)從事焊接自動(dòng)化裝備的高新技術(shù)企業(yè)。集設(shè)計(jì)研發(fā)、制造和銷售為一體,目前公司下設(shè)生產(chǎn)部、技術(shù)部、質(zhì)檢部、電控部、行政部、售后服務(wù)部、銷售部等多個(gè)部門。

泰安揚(yáng)帆數(shù)控科技有限公司(13345281377)主要產(chǎn)品有焊接自動(dòng)化成套裝備、數(shù)控切割機(jī)、工業(yè)焊接機(jī)器人和數(shù)字化逆變焊接電源、焊縫跟蹤系統(tǒng)及焊接擺動(dòng)器等,是一家綜合技術(shù)實(shí)力領(lǐng)先的自動(dòng)化、智能化焊接成套裝備的供應(yīng)商。產(chǎn)品廣泛應(yīng)用于國(guó)內(nèi)外機(jī)械制造、化工、汽車配件制造、農(nóng)用機(jī)械、建筑、金屬波紋 |