電鍍鋅SECC

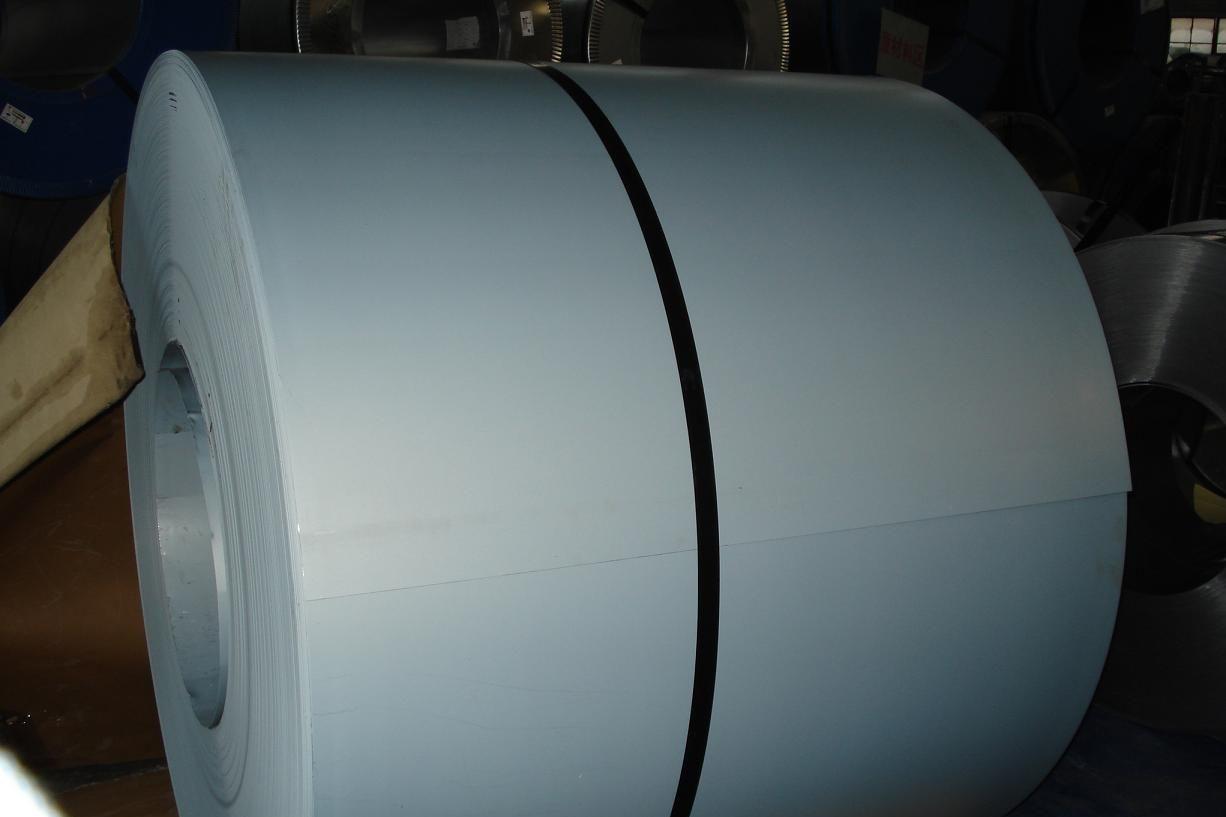

寶山鋼鐵股份有限公司生產的厚度為0.30mm~2.0mm的連續電鍍鋅/鋅鎳合金鋼板及鋼帶,以下簡稱鋼板及鋼帶。其表面顏色多種,例如:SECCN5呈淡藍色。寶鋼規定訂貨中未注明尺寸及不平度精度、表面質量級別、表面處理種類及包裝方式,則以尺寸普通精度、不平度普通精度、表面質量級別為FB、表面處理為鉻酸鈍化處理,并按供方指定的包裝方式供貨。對等厚鍍層,鍍層重量每面三點試驗平均值應不小于相應面公稱鍍層重量,單點試驗值不小于相應面公稱鍍層重量的85%;對差厚及單面鍍層,鍍層重量每面三點試驗平均值應不小于相應面公稱鍍層重量,單點試驗值不小于相應面公稱鍍層重量的80%。使用本產品時,用戶應根據其加工工藝、涂漆方法、涂漆設備等情況選擇合適的表面處理方式,并盡量縮短本產品的儲存時間。選擇合適的表面處理可減輕運輸和儲存過程中產生白銹的傾向,同時能夠改善涂漆層的粘附性,對鍍層起保護作用。對后道加工工序需磷化和噴漆的,不推薦選擇鉻酸鈍化處理方式。

Electric galvanized sheet SECC

Baoshan iron and steel co., LTD. Production of thickness from 0.30 mm to 0.30 mm continuous nickel/zinc alloy steel sheet and galvanized steel strip, hereinafter referred to as the steel plate and steel belt. The surface color of kinds, such as: SECCN5 are light blue. Baosteel rules not specified in the order size and roughness level of precision, surface quality, surface treatment type and packing, with common size precision, roughness average precision, surface quality level for the FB and surface treatment of chromate passivation treatment, and the way of packing supplier specified by the supplier. Equivalent thick coating, the coating weight each three corresponding nominal surface coating test should not be less than the average weight, single point test value is not less than 85% by weight of the corresponding nominal surface coating; For different thickness and single coating, the coating weight each three corresponding nominal surface coating test should not be less than average weight, single point test value is not less than 80% by weight of the corresponding nominal surface coating. When using this product, the user should be based on its process, coating methods, coating equipment, and so on and so forth to choose the right means of surface treatment, and try to shorten the storage time of this product. To choose the appropriate surface treatment can reduce tend to produce white rust during transportation and storage, at the same time can improve the adhesion of the coating layer, the protective coating. After the processing of phosphide and spray paint manufacturing procedures, don't recommend choose chromate passivation treatment.

SECC CS BLC+Z

SECD DS BLD+Z |

|

|