應用領域:

防偽材料、薄膜復合與轉移

模壓機、轉移印刷、涂布、燙印等

高檔煙草、酒類、化妝品、醫藥包裝材料

在各類高檔煙草、酒類、化妝品、醫藥等包裝材料的生產加工階段,由于其品質的要求,其對溫度的均一性、穩定性,以及生產環境的清潔等方面有著越來越高的要求:如轉移印刷、防偽鐳射、模壓壓紋、涂布等環節,電加熱輥因其溫度均勻性遠遠無法滿足高精度的工藝要求而已被徹底淘汰;傳統的導熱油加熱輥無法避免的會出現熱油泄漏和油氣揮發的現象,污染車間環境的同時更存在污染產品表面的隱患;不斷循環的復雜油路一方面造成能耗高企,另一方面維護工作頻繁,耗費大量人力財力。聯凈電磁加熱輥以其獨有的產品特性,可充分滿足高檔材料印刷所要求的高精度、無污染的工藝要求,且能有效降低能耗并提升產量與產品品質。

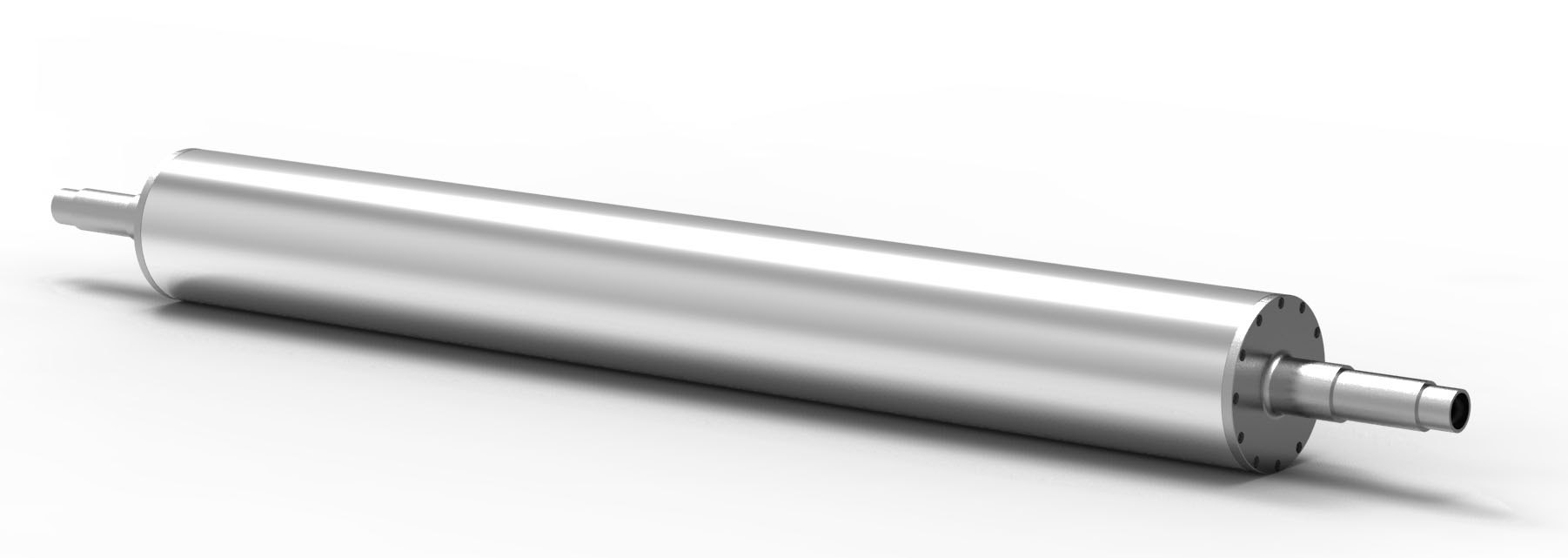

主要規格參數:

規格:180~220 * 800~1500

溫度:max 400℃

精度:±2℃

鏡面鍍鉻

有版縫與無版縫等多種結構

In the manufacture process of packaging material for cigarette, wine, cosmetic and medicine, the links like pad transfer printing, anti-counterfeiting laser, mould presses grain and coating all require stable and even temperature to ensure product quality. The LEGION electromagnetic induction heating roller can meet the technological requirements on high precision and no pollution with its unique product feature, besides, it can also reduce energy consumption and improve product quality.

Legion Induction heating rollers’ comparative superiority over traditional thermal oil heating and electrical heating roller

More even surface temperature (Within±1℃ )

Fast heating (Short half heating time comparing to thermal oil heated roller)

Energy conservation (Save electrical power by 30-70%)

No need maintenance (No need to change thermal oil or electrical heated tube)

Higher production speed (As fast as 120m/min) |

|

|