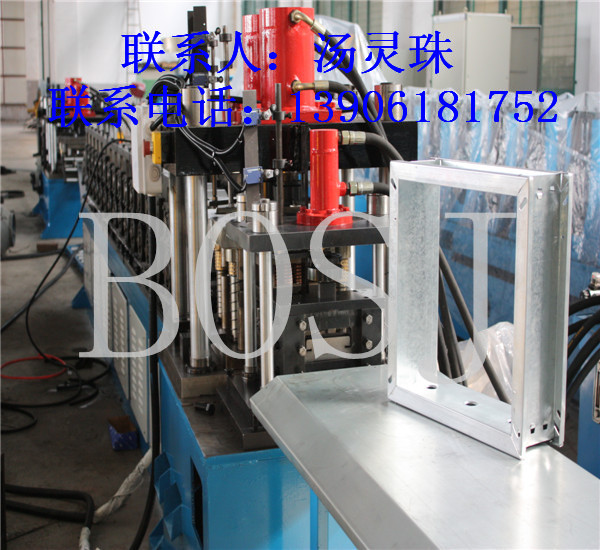

防火閥生產(chǎn)線設(shè)備

一、 成型工藝

放料——伺服送料——沖缺口及切斷 ——成型——收料

二、 設(shè)備組成部件

設(shè)備主要由自動(dòng)放料機(jī)、送料系統(tǒng)、沖缺口及切斷、送料、成型主機(jī)、收料臺(tái)、電器控制柜等部件組成。

三、 設(shè)備主要部件的技術(shù)參數(shù):

1、 自動(dòng)放料機(jī)

a、 負(fù)載能力:2噸

b、 處理卷料的內(nèi)孔直徑:490 - 510mm

c、 外徑:≤1200mm

2、 伺服送料及沖缺角部分

a、 伺服電機(jī):采用三菱伺服電機(jī),電機(jī)功率:1.0kw

b、 沖缺模架為四導(dǎo)柱式

c、 沖模缺角模具材質(zhì): Cr12 。 淬火處理。

3、 傳送料臺(tái):動(dòng)力為0.37kw

4、 成型主機(jī)部分

a、 成型機(jī)架:12道次

b、 成型模具材質(zhì):GCr15,淬火處理,硬度為HRC56-62o

c、 電機(jī):7.5kw變頻電機(jī)。

5、 電器控制:PLC

Fireproof valve production line equipment

A, the molding process

Feeding - servo feed - piercing and cut - molding - receiving

Second, the equipment components

Equipment is mainly composed of automatic feeding machine, feeding system, notching and cutting, feeding, forming host, receiving station, electric control cabinet and other parts.

3, equipment, the technical parameters of main parts:

1, automatic feeding machine

A, the load capacity: 2 tons

B, the processing of coil diameter of bore: 490-510 - mm

C, outer diameter: 1200 mm or less

Part 2, servo feed and lack of Angle

A, servo motor: adopt mitsubishi servo motor, motor power: 1.0 kw

B and lack of die set for four guide pillar

C, die missing Angle mould material: Cr12. The quenching process.

3, send material platform: power is 0.37 kw

4, forming the host part

A, molding frame: 12 times

B, molding mold material: GCr15, quenching treatment, hardness of HRC56-62 DHS

C, motor: 7.5 kw variable frequency motor.

5, electrical control, PLC

溫馨提示:【江陰博世杰防火閥成型設(shè)備】是由 |

|

|