泰安揚帆數控科技有限公司

目前增壓器已全行業實現了磨擦焊生產,增壓器輪盤與軸的焊接早在60年代就已開始。

At present, the supercharger has been the industry to achieve friction welding production, turbocharger disc and shaft welding as early as 60s has begun.

成為磨擦焊在汽車行業應用的一個亮點,甚至影響到機車、輪船等產業也紛紛效法推廣。

Friction welding has become a bright spot in the automotive industry, and even affect the locomotive, ships and other industries have to follow the promotion.

由于磨擦焊當年解決了鑄造高溫合金K13渦輪盤與結構鋼軸的磨擦焊質量問題。

The friction welding quality of high temperature alloy K13 turbine disc and structural steel shaft was solved.

結束了增壓器落后的復雜而又笨重的機械連接結構的歷史,大大提高了產品質量和機械效率,從而跟上了世界發展的潮流。

At the end of the history of the complicated and bulky mechanical connection structure of the supercharger, the product quality and mechanical efficiency are greatly improved, and the trend of the world development is kept up.

由于結構上的特點,半軸作為汽車上的重要零件。桿長且截面變化大,給制造帶來方便,激進工藝是棒料在較昂貴的平鍛機上多工位局部鐓粗成形制造整體鍛坯。

Due to the characteristics of the structure, the axle as an important part of the car. Long rod and cross section changes, bring convenience to the manufacturing process, the radical bar in the horizontal forging machine is more expensive on the multi station local upsetting forging manufacture.

泰安揚帆數控科技有限公司(咨詢電話 0538-5358300)座落在風景秀麗的泰山腳下,東平湖畔。東臨泰山,西依黃河,南與孔孟故里相望。京滬高鐵、濟廣高速公路貫穿而過,交通非常便利。

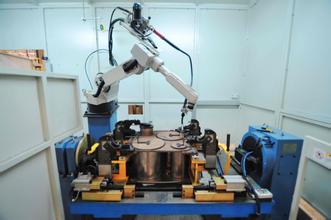

泰安揚帆數控科技有限公司目前是該地區一家專業從事焊接自動化裝備的高新技術企業。集設計研發、制造和銷售為一體,目前公司下設生產部、技術部、質檢部、電控部、行政部、售后服務部、銷售部等多個部門。

泰安揚帆數控科技有限公司將秉承“以質量求生存,以管理求效益,以科技求發展”的文化理念,繼往開來,努力拼搏,奮發向上,創造民族自動化焊接世界品牌!

泰安揚帆數控科技有限公司

地址:山東省泰安市東平縣東平工業園區

電話:0538-5358300

銷售熱線:13345281377

傳真:0538-5358300

QQ號:133452813 |

|

|